Longmen processing 02

Longmen processing 03

Longmen processing 04

Longmen processing 05

Longmen processing 06

Longmen processing 07

Longmen processing 08

Longmen processing 09

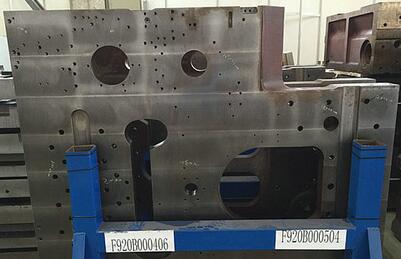

Longmen processing 01

Processing center of small proc

Processing center of small proc

Processing center of small proc

Processing center of small proc

Processing center of small proc

Processing center of small proc

Processing center of small proc

grinding is a technology in machining. Grinding is done by grinding wheels or other grinding tools. The main motion is the rotation of grinding wheels. The grinding process of grinding wheels is actually the combined effect of abrasive grains on the surface, cutting and sliding of three parts. In grinding, the abrasive grains themselves are also gradually sharpened by sharpening, causing the cutting effect to become worse and the cutting force to become larger. When the cutting force exceeds the adhesive strength, the blunt abrasive grains fall off, exposing a new layer of abrasive particles, forming &ldquo of the grinding wheel; self sharpening ” But the chips and crushed grains will still block the grinding wheel. Therefore, after grinding for a certain period of time, the grinding wheel must be repaired with diamond turning tools.

grinding is a technology in machining. Grinding is done by grinding wheels or other grinding tools. The main motion is the rotation of grinding wheels. The grinding process of grinding wheels is actually the combined effect of abrasive grains on the surface, cutting and sliding of three parts. In grinding, the abrasive grains themselves are also gradually sharpened by sharpening, causing the cutting effect to become worse and the cutting force to become larger. When the cutting force exceeds the adhesive strength, the blunt abrasive grains fall off, exposing a new layer of abrasive particles, forming &ldquo of the grinding wheel; self sharpening ” But the chips and crushed grains will still block the grinding wheel. Therefore, after grinding for a certain period of time, the grinding wheel must be repaired with diamond turning tools.